Injectable mortar VM-EA

VM-EA chemical injection mortar, 300 ml, foil cartridge with mixer nozzle

The universal injection system for non-cracked concrete, damp concrete, water-filled boreholes and masonry made from solid or perforated brick.

Art.-no. 0911005300

EAN 4029484827572

Register now and access more than 125,000 products

The universal injection system for non-cracked concrete, damp concrete, water-filled boreholes and masonry made from solid or perforated brick.

The VM-EA injection system is an injection system for fixtures in non-cracked concrete and masonry. The system includes an epoxy acrylate-based, styrene-free chemical injection mortar in a mortar cartridge, as well as a VMU-A anchor rod, V-A or commercially available threaded rod with acceptance test certificate 3.1 (e.g. VM-A), as well as a nut and washer. When used in perforated brick, a perforated sleeve is also required.

Field of Application:

For anchorages in non-cracked concrete such as base plates, supports and wall brackets and for mounting joint tapes.

Anchoring in masonry:

Canopies, door and window frames, facade substructures, battens, gates etc.

Advantages:

Versatile injection system for different applications in concrete and masonry

Approved for non-cracked concrete

Approved for installation in damp concrete and in water-filled drill holes

Approved for aerated concrete and solid and perforated brick masonry; dry or wet

Approved with anchor rods and for commercially available threaded rods with proven strength (acceptance test certificate 3.1)

Approved with adjustable push-through perforated sleeve VM-SH 16 x 130/330 for bridging insulation systems and other soft

surfaces

Substrate temperature during application: -5°C to +40°C

Ambient temperature after full curing: -40°C to +80°C

Variable anchoring depths for added flexibility

Opened cartridges can continue to be used with a new mixer nozzle

Styrene free

Advice:

Perforated sleeve VM-SH 16 x 130/330 enables fixtures in perforated brick through insulation boards.

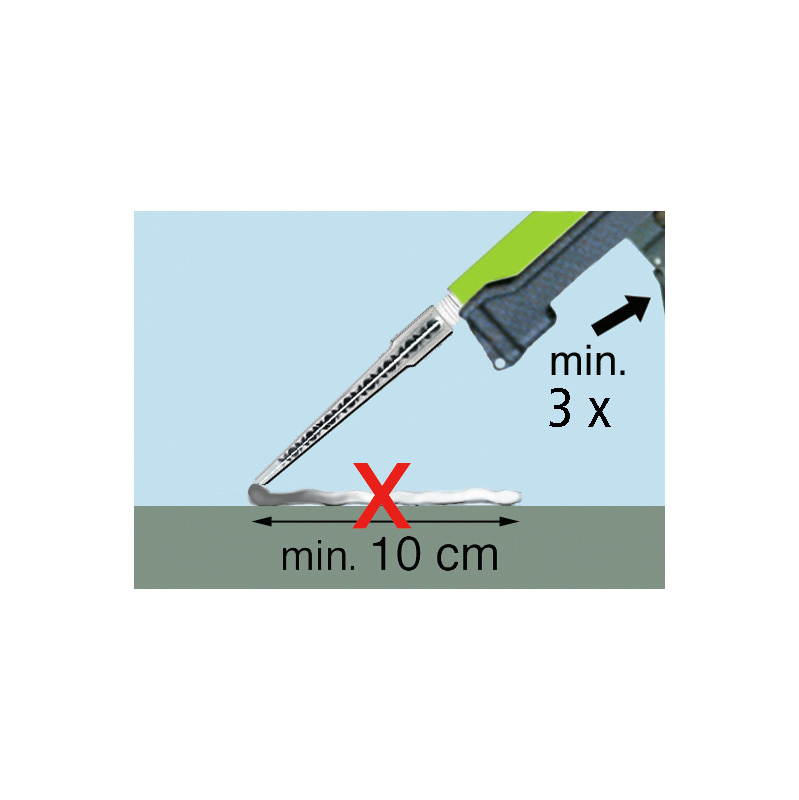

The tubular film cartridge (0911 005 300) must be cut open before use. To do this, pull the foil on the thread outwards and cut using scissors.

Type description | VM-EA 300 chemical injection mortar |

Chemical basis | Epoxy acrylate |

Content remark | Tubular film cartridge incl. mixer nozzle |

Shelf life from production | 12 Month |

Contents | 300 ml |

Number of pieces per covering box | 12 PCS |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!